.

As early as the early nineteenth century bricks were being made at Dutson by a man from London with much of the work going to help in the construction of the Bude Canal. The handmade orange coloured clay bricks were burnt in beehive kilns. Many of Launceston’s fine buildings are also constructed from ‘Dutson brick’ including North Hall (below) in Dunheved Road.

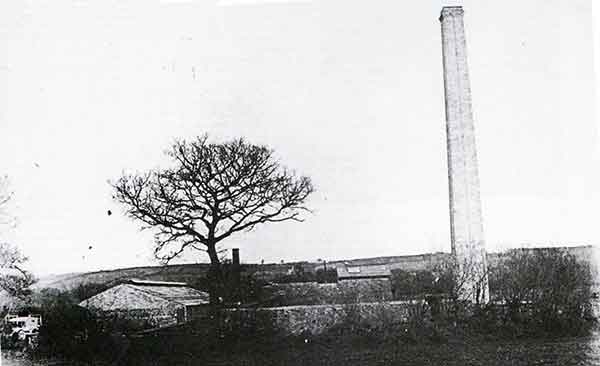

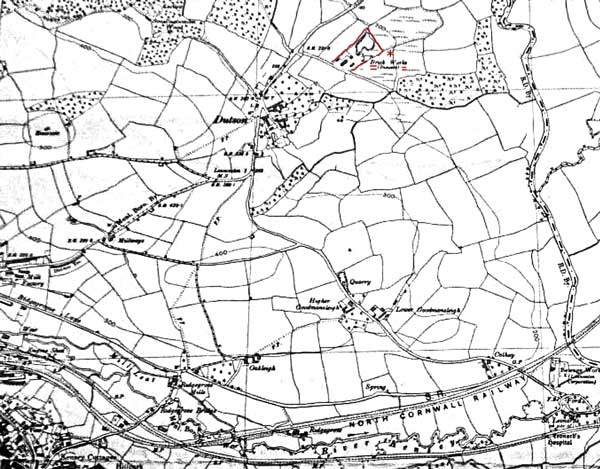

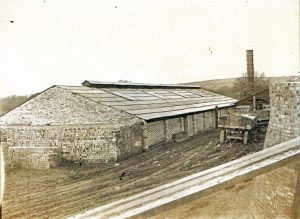

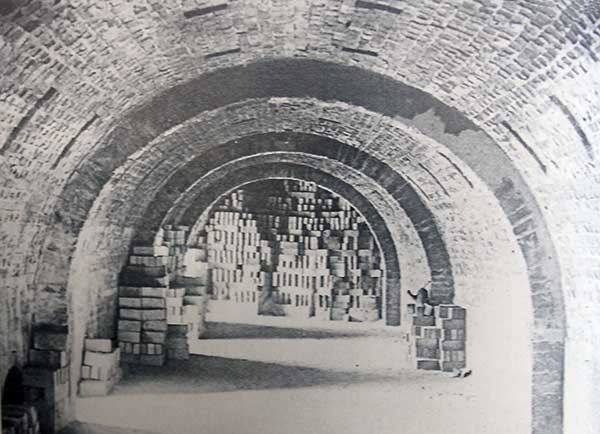

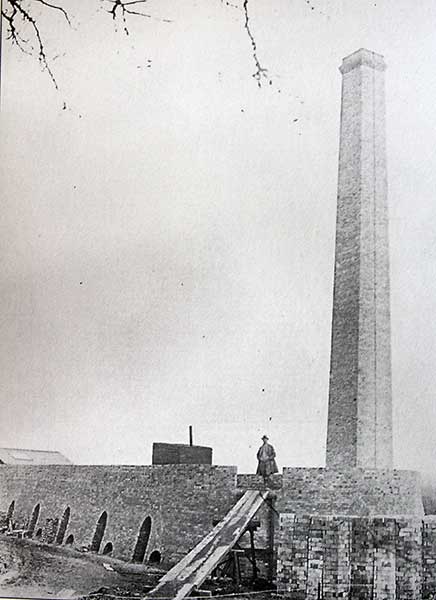

In 1920 a Mr Taylor established a limited company after the discovery of what was called ‘as white as candy’ clay was discovered by the Tamar. At the time it was stated that the beds of clay were inexhaustible and that the clay was of the finest in the district. Two round kilns about 25’ across were built to make the first bricks, this was followed by a much bigger oval kiln and chimney stack 105’ in height. Drainpipes and roofing tiles were also manufactured at Dutson. At this time there were twenty men employed, mostly working on the clay beds where around 10 inches of topsoil had to be removed to expose the clay. Three large buildings were built to house the steam-powered machinery, which prepared, cut and moulded the clay, which was then conveyed from the pit and over an incline to a second chamber which housed the wire-cutting machine. This automatically cut the clay into the required size depending on the item being made. The final part of the operation would be to fire the clay in the large kiln. When the kiln was lit, a 24-hour endless stream of coal was fed to its furnace, with the men wheeling barrow fulls of coal up the unguarded ramp (seen below with a workman standing at its top). A steam engine with a trailer was used to deliver the bricks around the area, often seen making the journey to Tavistock with a load of bricks and returning with a load of coal for the kiln. Some of the bricks had been used to build the houses at Dutson Terrace, but it was found if they were left unrendered they would flake off.

Western Counties Brick Company later took over the operation and the intention was to build a series of homes for the employees near to the works, but only one bungalow (now called Sunnybank) was actually constructed for the foreman, a Mr Blackmore, of the works on land owned by the Broad family of Lower Dutson Farm.

The works closed in 1929 after the company went bankrupt. The site was then purchased by the Whitstone Brick Company. In 1939, Gerald Congdon (1913-1970), whose father farmed at Horrel Farm, Werrington rented the site from the Whitstone Brick Co. to use as a pig farm. During the war years, he collected swill from the various army camps and hospitals etc. Also, refuse bins were placed in towns for people to place potato peelings and any other edible food suitable for pig food. He fixed a boiler at the bottom of its chimney stack and used long poles as fuels pushing them in as the ends burnt. An old car was jacked up with a belt attached to the back wheel and leading to a water pump, provided the water from the pit pool to fill the 300-gallon tank on top of the kiln, this, in turn, supplied the water bowls. It was not an ideal piggery being very damp and dark inside and bushes growing over the top. He also stocked the pool with rainbow trout.

After the war the swill became scarce and imports of grain started to come in, so Gerald changed over to poultry in pens, but after a few years through various reasons, his situation got the better of him. He had lived at St. Stephens with his wife, but after she had left him, he started to live in a hut near the kilns for a couple of years before finally leaving the district entirely.

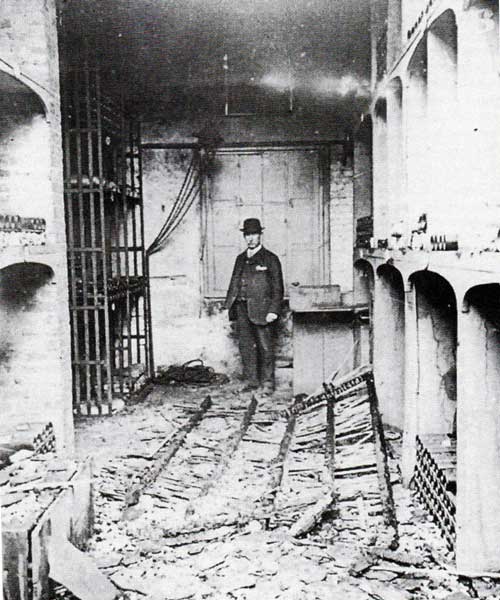

Again the site was abandoned and had been taken over by the Launceston Abbatoir Company for use as a possible knackers yard. Most of the buildings were then demolished (below left) with just the 105-foot kiln chimney remaining in place. This too was pulled down in 1954 (below right). It was then put up for sale Eldred Broad of Lower Dutson Farm, purchased it and today it is a small caravan site and fishery.

Visits: 272